We need recent complete analysis details of water to be treated, Total quantity of treated water required per day & per hour, End use of the treated water (Application), Desired treated water quality with specification

Sewage Treatment Plant

- Home

- Sewage Treatment Plant

Industrial - Sewage Treatment Plant

INDION NGPSTP is a unique combination of lamella plate clarification and aeration that results in a ready-to-operate, pre-fabricated solution of outstanding performance and efficiency for sewage treatment.

Industrial Sewage Treatment Plants (STPs) are essential systems designed to treat wastewater generated from industries, commercial establishments, and institutions. They effectively remove contaminants, organic matter, and harmful pathogens from sewage to ensure compliance with environmental standards. Modern packaged STPs, like the INDION New Generation Packaged STPs, are compact, easy to install, and energy-efficient solutions tailored for various industrial needs.

These advanced STPs come with cutting-edge technologies such as Moving Bed Biofilm Reactor (MBBR), Membrane Bio-Reactor (MBR), and Sequential Batch Reactor (SBR) processes. They are pre-engineered, skid-mounted, and modular in design, ensuring minimal space requirements. The systems are designed for automatic operation, ensuring ease of use with minimal manpower. They also include energy-saving aeration systems and robust construction using corrosion-resistant materials for longevity.

Fluidised Media Reactor (FMR)

INDION Fluidised Media Reactor (FMR) is designed as a single tank unit with specially developed synthetic media to facilitate attached growth process, oxygen transfer through diffused membrane aeration, lamella settler and chlorine contact tank for disinfection.

INDION® FMR is a next-generation biological wastewater treatment technology designed for efficient removal of organic pollutants from industrial and domestic sewage. It operates on the principle of fluidized bed biofilm technology, using specially designed media to support the growth of microorganisms that degrade organic contaminants.

Its compact and modular design makes it ideal for industries seeking efficient sewage and effluent treatment solutions.

Salient Features

Single tank design

Uses 1/3 the space of a conventional sewage treatment plant

Uses high porosity moving media for bacteria to grow

Useful for modification/capacity extension of existing sewage treatment plant

Fully Automated Operation

Low Energy Consumption

NGPSTP Blower less Reactor

INDION NGPSTP is a unique combination of lamella plate clarification and aeration that results in a ready-to-operate, pre-fabricated solution of outstanding performance and efficiency for sewage treatment.

Primary Settlement: Sewage enters the primary settlement tank. The tank incorporates lamella parallel plates which aid in reducing the suspended solids by 75% and the BOD by 25%.

Aerobic Treatment: The effluent then enters the aerator bio-zone which is a combined fixed film reactor and active aeration system mounted on a horizontal shaft.

Final Settlement: The treated effluent then moves to the settlement area. This area contains a lamella parallel plate assembly for settling finer particles.

Sequencing Batch Reactor (SBR)

INDION SBR is a cyclic activated sludge treatment system. Its compact design is based on sequential time cycle for equalisation, aeration, settling and clarification which provides many advantages over conventional activated sludge processes.

Primary Settlement: Sewage enters the primary settlement tank. The tank incorporates lamella parallel plates which aid in reducing the suspended solids by 75% and the BOD by 25%.

Aerobic Treatment: The effluent then enters the aerator bio-zone which is a combined fixed film reactor and active aeration system mounted on a horizontal shaft.

Final Settlement: The treated effluent then moves to the settlement area. This area contains a lamella parallel plate assembly for settling finer particles.

Advantages

- No moving parts

- Processes like nitrification, organic matter removal, settling or clarification are carried out sequentially over-time in a tank

- Less footprint, as clarifier is not required

- Fluctuation is buffered in a pre-equalisation tank, therefore producing consistent treated effluent quality

- Treated effluent of highest quality BOD < 10, COD < 100 & TSS < 5

- Can be constructed in bolted tank, mild steel, epoxy paint (MSEP) and civil

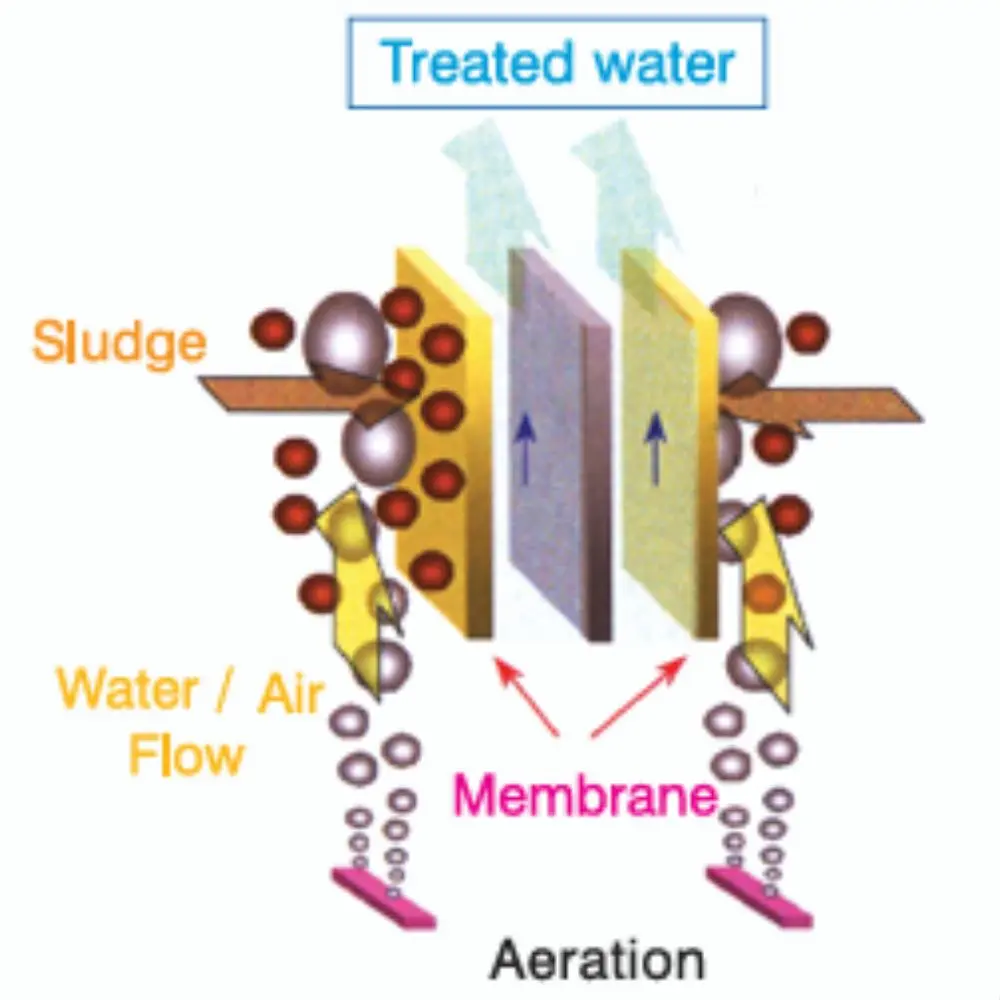

Membrane Bio Reactor (MBR)

INDION Membrane Bio-Reactor (MBR) is among the latest technologies in biological treatment, designed to produce high quality treated water from waste water with highest possible contaminant reduction without using any chemicals.

What makes the INDION MBR so successful is the effectiveness of the submerged membranes filtration in the biological process. It is this membrane treatment that produces high quality permeate from domestic sewage and industrial waste water.

The submerged membranes used in the biological process remove suspended matter from activated sludge and provide stable and reliable unit with consistent performance.

Salient Features

Single packaged unit with minimal civil construction

Modular in construction and design

Compact, requires 25% of a conventional system

Low energy consumption (1.14 kwh/1000 gal) for filtration

Up to 6 log (99.9999%) removal of total coliform

No chemicals required during treatment

Applications

Hotels & Restaurants

Townships & Housing Complexes

Industrial Estates

Existing Plan Upgradation

National Parks

Waste recycle

IT parks, hospitals & malls

Golf & Country Clubs

Authorized Channel Partner of

Our Industrial Clients

You can reach us for...

RO plant membranes, Ultra-Filtration(UF) plant membranes, DM plant & Softening plant resins and all genuine spares required, Preference to share to offer AMC or O&M mutual consent

To solve quality issues in treatment plant, To solve quantity (OBR) issues in treatment plant

Sharing recent report with the current performance data & expected expansion capacity to study and offer upgradation treatment system

We have in-house analysis fecilities to support for complete analysis of raw water boiler feed and blow down water & cooling tower bleed off water to suggest for any remedial measure, if needed

Experts training programs can be availed on prior appointment for the benefit of operations to enhance filter knowledge & operational procedure